Offer

Punching and stamping

Stamping and punching of metals are the key types of our company’s operations.

Stamping and punching of metals are the key types of our company’s operations.

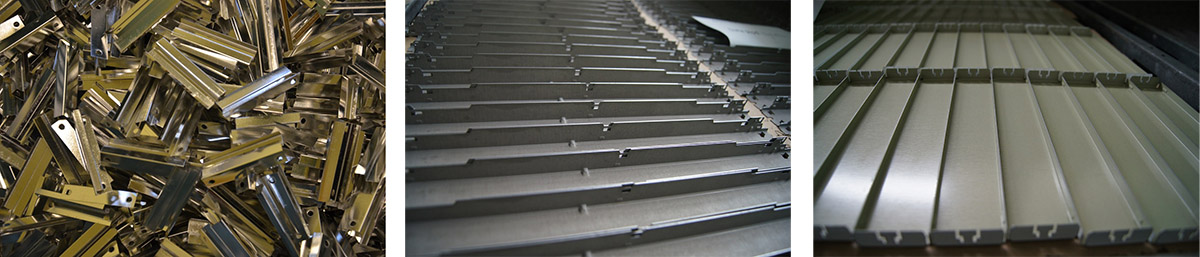

We specialize in manufacture using the progressive pressing technology on progressive tools.

Progressive stamping is a metalworking method that involves punching, bending and other metal forming processes taking place in a single tool. The feed system unrolls the metal strip through all progressive die stations. Each station performs one or more operations until the finished part is complete. Pressing and punching on progressive tools is characterized by speed, downtime reduced to a minimum, low labor cost, minimized production waste, high repeatability, and low unit cost.

Progressive lines supplement presses used for the production of low-volume products.

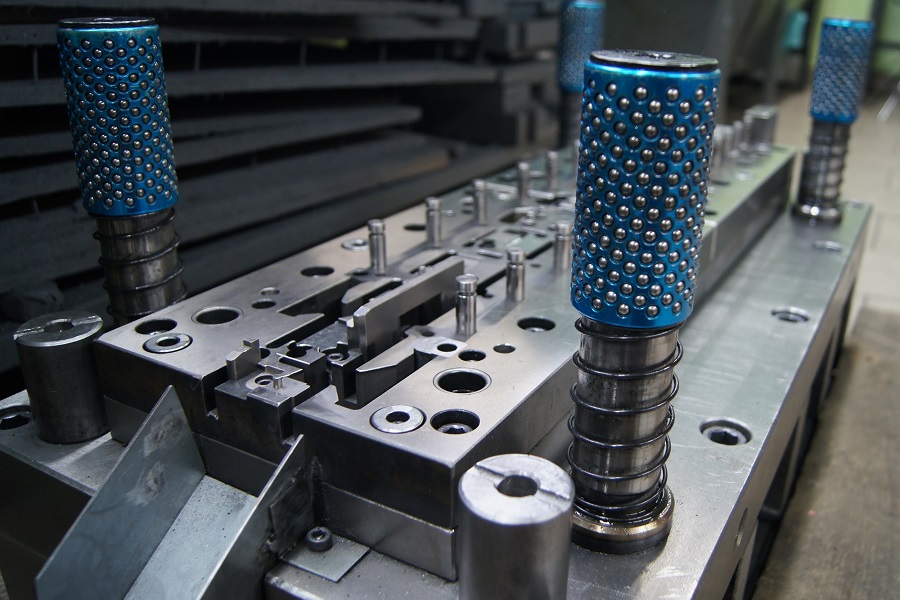

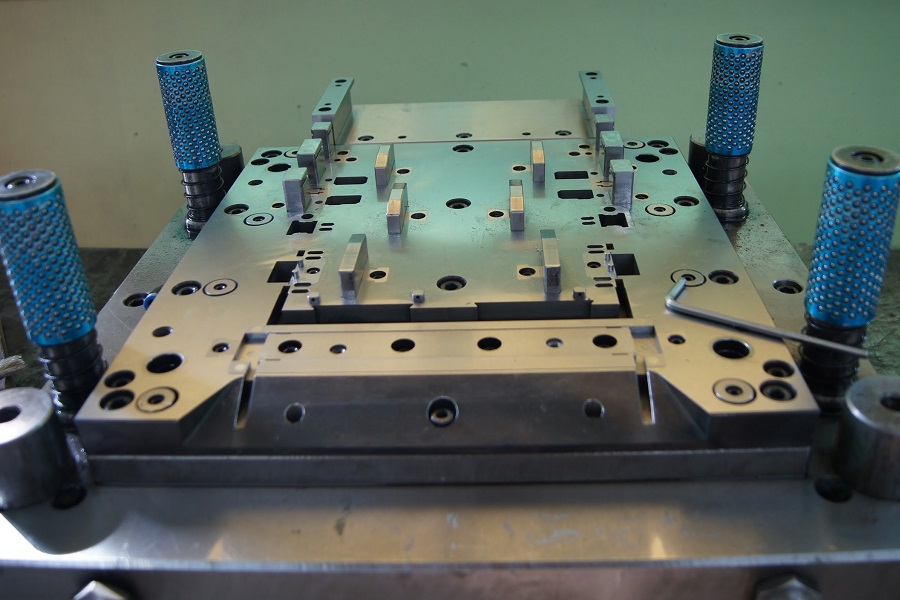

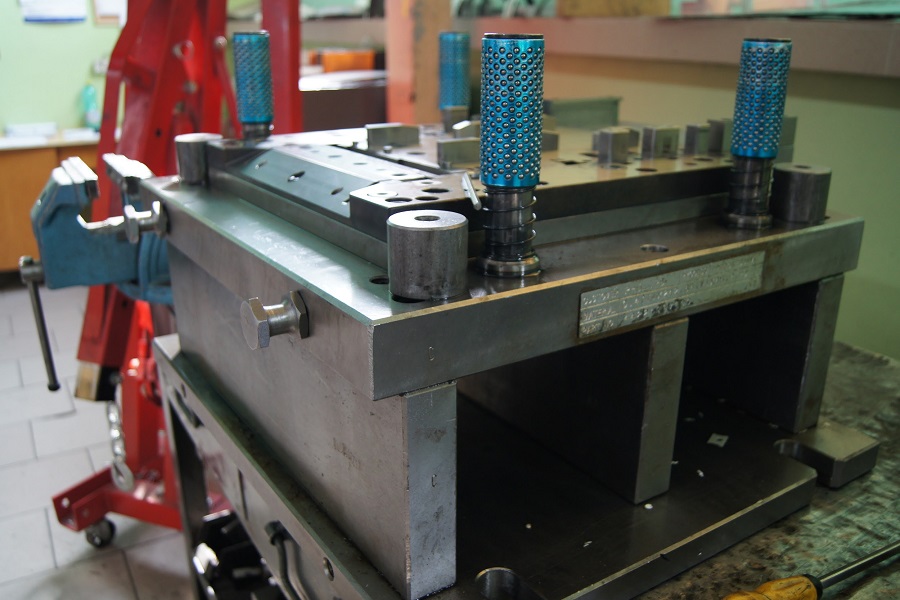

Tool shop

Our own tool shop provides ongoing and professional maintenance of all our own tools and tools of our customers, thus guaranteeing continuity and safety of production.

We make tools based on the documentation received from our customers and our own documentation. We cooperate with tool shops in Poland and abroad.

Cooperation with proven manufacturers of tools, including those from the PRC on some projects, allows us to offer to our customers tools at very attractive prices, which, although made abroad, are operated and serviced at our company.

- We make, among others:

dies; - punches; and

- progressive tools.

Assembly

We provide assembly of metal components and other components, surface treatment, and packaging. We are able to design and implement any assembly process. We have the appropriate surfaces and experience.

We provide assembly of metal components and other components, surface treatment, and packaging. We are able to design and implement any assembly process. We have the appropriate surfaces and experience.

Technologies

In the production process, we use various technologies such as:

- metal forming (including cutting, bending, stamping, and threading);

- metal joining (welding, fusion welding, and riveting);

- metal coating (varnishing, zinc coating, nickel plating, tinning, oxidation, and anodizing);

- machining (turning, milling, grinding, and electro-discharge machining);

- washing of details;

- we also offer assembly of ready-made subassemblies.

Materials

We specialize in the processing of materials of the following grades:

We specialize in the processing of materials of the following grades:

- black carbon steel;

- carbon steel with metallic coating (Zn, Sn, Ni, Cu);

- carbon steel with organic coating (varnished);

- alloy steel (stainless steel, spring steel);

- non-ferrous metals (aluminum, copper);

- alloys of non-ferrous metals (brass, bronze).

We process materials in the following forms:

- bands with the thickness of 0.2 – 6.0 mm, max. width up to 600 mm;

- sheets 2000 mm x 3000 mm;

- bars;

- pipes.

Machinery

Our machinery ensures high quality of manufactured products and low production costs.

We have 3 progressive lines with presses with pressure in the range of 125 to 200 t and a large number of presses with pressure in the range of 2.5 to 160 t.

| Equipment name | Max. press pressure [T] | Table size[mm] | Width [mm] | Thickness [mm] | Weight [T] |

|---|---|---|---|---|---|

| San Giacomo SGP200 progressive line | 200 | 1700 x 1000 | max. 600 | 0,4 – 3,0 | max. 5,0 |

| San Giacomo SGP160 progressive line | 160 | 1300 x 760 | max. 600 | 0,4 – 2,5 | max. 5,0 |

| Helvita H125 progressive line | 125 | 920 x 690 | max. 240 | 0,4 – 2,0 | max. 1,0 |

The machinery allows us to make various complex details for various industries, such as:

- the lighting industry;

- the electrotechnical industry;

- the electronics industry;

- the telecommunication industry;

- the automotive industry; and

- the household appliances industry.

A wide range of presses gives us the ability to manufacture large- and small-volume series of products, including samples, test batches, etc.

Quality

The quality of our products is a priority for us and we focus on it throughout the entire production process.

The highest and repeatable quality is maintained by the implemented and periodically certified quality management system compliant with ISO 9001:2015. We are also systematically audited by our customers.

The quality control department, apart from standard measuring equipment, also has instruments for specific inspections of manufactured products and conducts continuous monitoring of the quality of manufactured products.

Organization of production processes

A team of engineers ensures comprehensive organization of the entire implementation process, from feasibility assessment to mass production, including valuation, sample production, technology selection, and design and manufacture of instrumentation. Our many years of experience and qualified staff allow us to quickly fulfill any orders. A project manager is assigned to each implementation.

A team of engineers ensures comprehensive organization of the entire implementation process, from feasibility assessment to mass production, including valuation, sample production, technology selection, and design and manufacture of instrumentation. Our many years of experience and qualified staff allow us to quickly fulfill any orders. A project manager is assigned to each implementation.

The ERP system allows us to plan production and fulfilment of production orders according to the schedule.

We provide advanced product quality planning (APQP) based on flow charts, the FMEA process, and control plans. Process control uses process maps, control plans and charts, as well as Cpk analyses that enable us to control process stability. We use the FMEA process methodology and 8D reports. We provide PPAP documentation.

The company has a continuous improvement system, within which quality objectives are set and implemented by means of the Deming/PDCA (Plan-Do-Check-Act) cycle, the 5S rules are applied, and ongoing improvement of processes is conducted to improve the level of their efficiency and reliability. We periodically conduct employee training and use visualizations of quality problems at workstations. We focus on the LEAN corporate management concept.

We are characterized by efficient logistics, flexibility in determining the MOQ and the size of orders, and short lead times of projects. We enable our customers to maintain the necessary safety stock, ensure short time of order confirmation, immediate response in emergency situations, DAP, EXW and other delivery conditions depending on customer preferences, labelling, barcodes on packages, and suppliers’ qualification sheets.

Periodic audits are conducted to assess, among other things, such areas of the company’s activities as logistics (OLIP), quality (FOR, PPM, LAR), cost, proactivity, and support and innovation. Our goal is 100% on-time delivery, the shortest possible lead time, and continuous improvement of products and services.

We collect declarations of compliance with RoHS and REACH.

The company’s consistent growth policy allows for a gradual increase in the scope of the offered services and for continuous improvement of the processes.

Strengths

- many years of experience in processing steel and non-ferrous metal materials;

- professional approach to projects;

- long-term cooperation with customers who demand the highest standards;

- technical advice during the design and implementation of new products with regard to technology, materials, and coatings;

- proactive approach and close cooperation with customers;

- high quality of products;

- innovation and continuous development of production capacities, products, and technologies;

- experienced staff;

- own tool shop;

- competitive prices;

- ERP software;

- 100% Polish-owned.